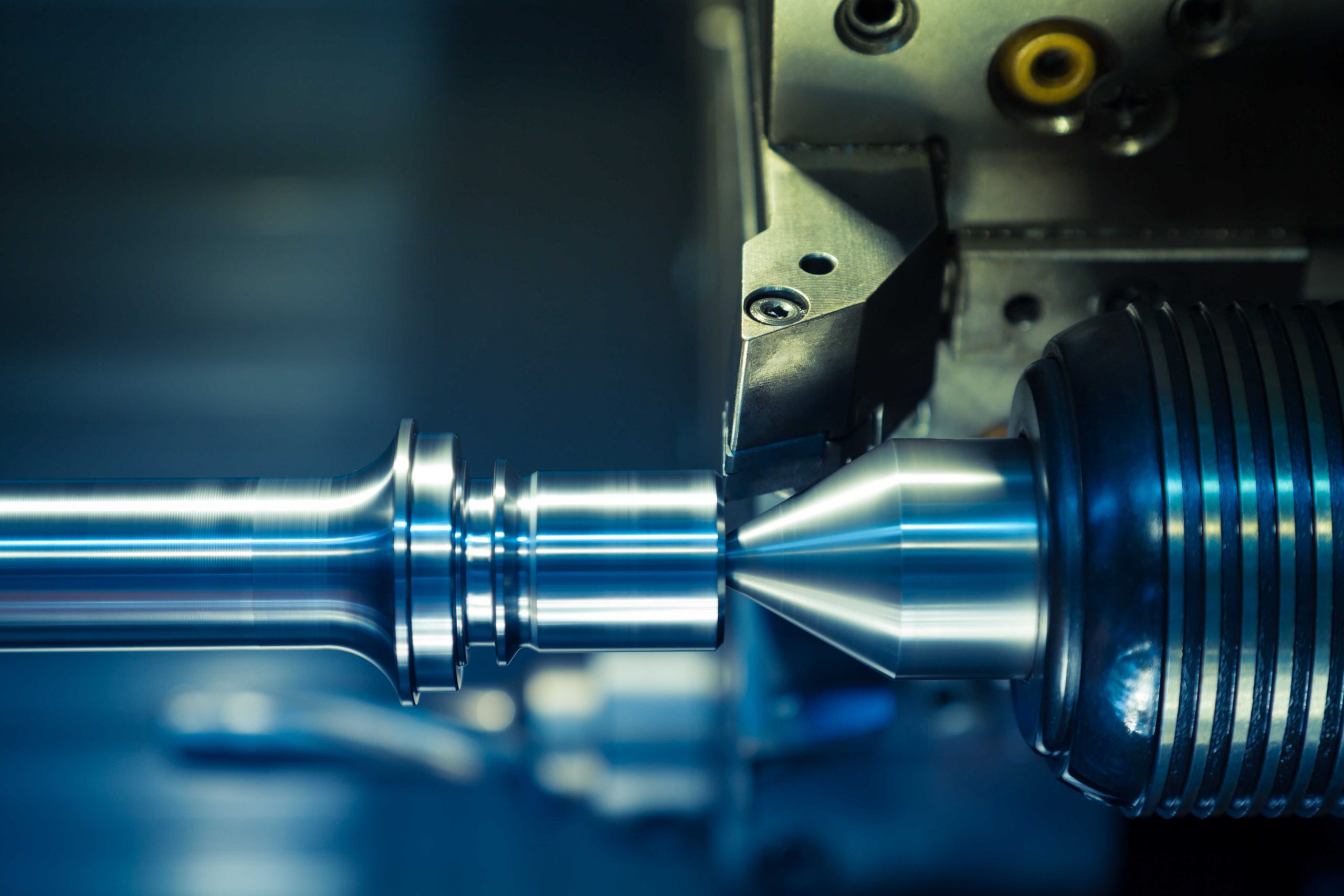

Our extensive technical expertise and capabilities are just two of the reasons we’re a national leader in phenolic machining. AMI also provides fast turnaround times and cost-effective service, with no order minimums and low tooling costs.

Most importantly, we’re a partner to everyone we serve. We’re committed to leveraging our longstanding experience in CNC machining to help our clients solve problems related to sourcing, design and manufacturing. To learn more about how we can help you, contact our office today.